Always on the lookout for new gear, I spent most of Sunday at the NRA Annual Meetings & Exhibits looking for the less known vendors and what they have to offer. One of the last booths I stopped by was for Mil-Tac Knives & Tools. Based out of Dallas, Texas Mil-Tac had two knives that caught my attention, and Neal Marx was gracious enough to walk me through their features.

MTF-4 Tanto

The first knife that jumped out at me was the MTF-4 Tanto folding knife. This knife comes with G10 handles, and N690 German stainless steel blade. Although the steel comes from overseas, the shaping, sharpening, and manufacture of the knife is all done in Dallas, with the remaining parts being made in the USA. That blade is also coated in ceramic to increase longevity, strength, and blade sharpness.

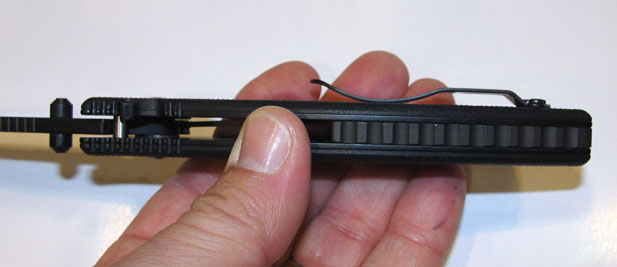

The MTF-4 has a really nice look to it, and its opening and closing movements are very smooth. In addition to a traditional locking bar in the middle of the handle that moves into position as the blade opens, the MTF-4 has a locking lever on the top right portion of the handle that will ensure that the blade cannot be accidentally closed.

The MTF-4 can come in a partially serrated blade or a razor edge, and includes these features as well:

- Overall length – approximately 9.5″

- Folded length – approximately 5″

- Exposed blade length – approximately 4.5″

- Belt clip, with (4) mounting locations and (2) styles of carry – hilt in or base in

- Glass break shaped base

- Lanyard hole at lower end of handle

- MSRP – $170

Although priced toward the top end of folding knife prices, the MTF-4 has several features that spell out value. From what I saw this knife would please most users.

CS2 Fixed

The next knife that caught my attention was the CS2 fixed blade knife. I always get a smile on my face when checking out big fixed blade knives. Perhaps its the history of knives, or the mystique, or maybe the audacity of some knife makers, but they always seem to be eye-catchers. The CS2 is just that kind of knife, and as you read on you’ll see that I’m not the only one who thinks so.

The CS2, like all of the Mil-Tac fixed blade knives, are 100% made in the USA. It also comes with a G10 handle that has a variety of unique designs for the user to choose from. That handle, like all Mil-Tac knives, is full tang and can be used to break glass or heads with a grip strike.

But it’s what most viewers may not see, that is the biggest selling point of the CS2. The blade is made of a combination of carbon fiber and titanium. Titanium is one of those magic materials that is much stronger than steel, yet weighs less. The U.S. Navy figured out its benefit years ago, and every submarine has been made of the stuff for several decades now.

The combination of carbon fiber and titanium is so proprietary that even Neal did not have all the specifics on the process of making it, and he’s been dating the owner’s daughter for 3 years now! The owner of Mil-Tac, Craig Sword, developed the process of combining the carbon fiber with titanium and he’s not about to spill his secret.

What I can tell you is that there are 4-5 layers of carbon fiber laid together with the titanium blade in a basket weave type pattern. Each carbon fiber layer is off set so that any weak point at the connections are backed up by another layer’s strong point. Once the carbon fiber and titanium are set together, they are put through a heat process that blends the materials into one, and reportedly makes the blade extremely strong. It definitely fulfilled the bad ass appearance test.

Neal told me that recently the U.S. Navy tested the CS2 for their Special Operations groups (i.e. SEALs, and Special River Boat operators – SEAL drivers) using a multi-phase endurance test. The CS2 endured up to 36 hours of salt water, freezing, heat, and sand. According to Neal, the knife performed so well that some Navy personnel bought up almost all the CS2 knives they had.

That is one BA knife! As you can imagine, if the knife is made of proprietary techniques and materials, and the Navy SEALs like them, the price is going to reflect that quality. Unless a large military contract helps drive the cost down, expect to pay around $400 for this knife.

4 replies on “Mil-Tac Knives and Tools”

Correction!

The Mil-Tac MTF-4 folder is made from Italian steel, not German. Not being a metallurgist, I’m not sure of the difference in quality between the two types of steel.

I had been talking with Neal, when owner, Craig Sword began talking to another customer right next to us. Neal had told me the steel on the MTF-4 was from Italy, but I heard Craig say it was from Germany. Apparently Sword was talking about another Mil-Tac product.

The N690 stainless steel is from Bohler and they have locations in Germany, Austria, and Sweden and all over the USA.

Company link

http://www.us.bohler.com/en/

Thanks for the clarification Craig!

You have some really nice products, as the Navy seems to recognize as well. We’ll be looking forward to writing about your products in the future.

Thanks and let me know what we can do!

Craig Sword

MIL-TAC

http://www.mil-tac.com